News RSS

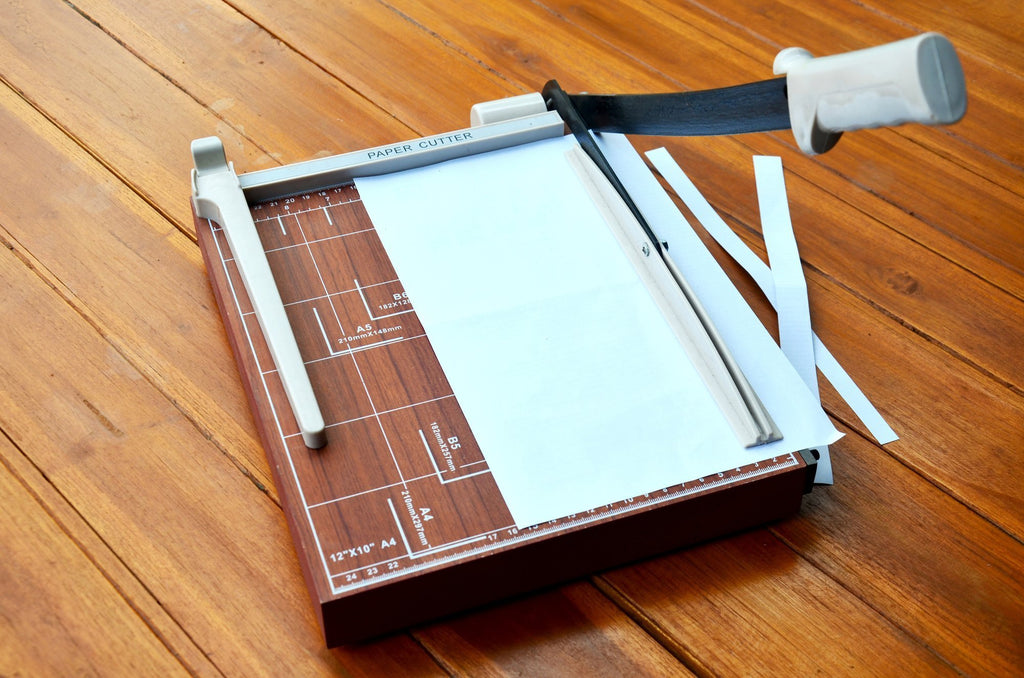

How to Identify a Dull Paper Cutter Blade

To keep cutting paper efficiently, you need to make sure your blade is in top shape at all times. But how can you tell when you're working with a dull paper cutter blade? Keep reading to learn what to look for. After a while, all blades, knives, and cutters become dull. When blades on paper trimmers, stack cutters, and guillotines go dull, the quality of their work goes way down. It can be hard to tell if a misstep in performance is because of a dull blade or a mechanical issue with the paper cutter. But we've written this...

5 Ingredients You Need to Run a Successful Shipping Store

Are you looking to start a shipping store? Or maybe you already have one, and you'd like to take it to the next level? Keep reading to learn about the 5 ingredients you need to run a successful shipping store! Trying to start a new shipping store? Sweet. This is a big move for any business, so congrats on wanting to step things up a notch. As you're new to the world of shipping, you need to know that things can get a little out of hand if you don't know what you're getting into. That's why we took it...

Top 5 Tips to Help Your Print Shop Run More Efficiently

Efficiency is extremely important when it comes to the success of a local print shop. To find ways to run your local print shop more efficiently, keep reading! The success of your business depends on how efficiently you run it. Are you a good leader? Is your equipment top of the line? Are your employees happy? These are things that factor into running a print shop. You can easily make adjustments to your store, your organization, and your tools to increase productivity. To learn how to boost your local print shop's success, keep reading. 1. Organization of the Shop Does...

Top 5 Paper Cutter Safety Tips

How Print Shops Can Scale and Make More Money: 5 Proven Ways

How Print Shops Can Scale and Make More Money: 5 Proven Ways Struggling to get customers to your printing shop? Or maybe business is doing well, but you're still looking for ways to grow. Whichever category you fit in, here are 5 proven ways print shops can scale and make more money. Print is making a comeback in a big way. The print industry is recovering in the wake of the digital disruption of the first decade of the 21st Century. This is causing a resurgence in physical print shops as people rediscover the numerous benefits of using local print...