News RSS

What Accessories Can I Purchase for My MBM Triumph Paper Cutter?

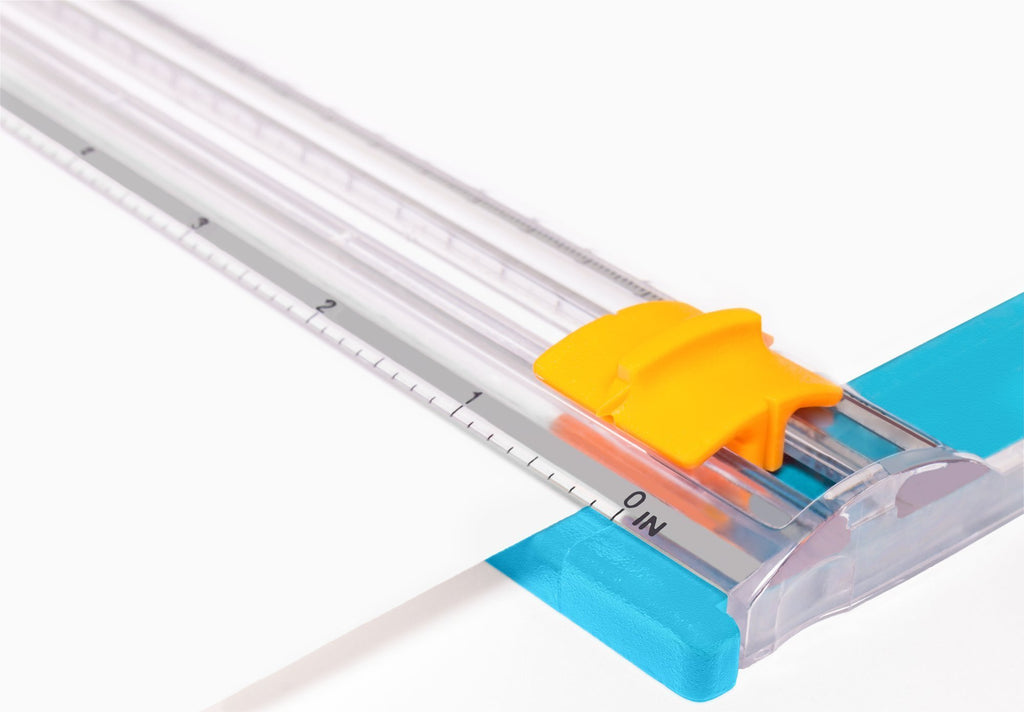

A paper cutter, also known as a paper guillotine or trimmer, is a machine that is created to cut large quantities of paper in a straight line quickly and efficiently. The organizations that benefit from paper cutters include print shops, schools, corporations, nonprofits, marketing agencies, and graphic design studios. They use paper cutters to cut documents, photos, brochures, presentations, posters, and booklets. Accessories that accompany paper cutters are cutting knives, cutting sticks, and side tables. Investing in these accessories is essential for keeping your MBM Triumph Paper Cutter functioning effectively. They produce high-quality cuts, extend the life of the machine,...

What is MBM Triumph VRCut Ready Technology?

VRCut Ready Technology is a PC Software solution created to work with MBM Triumph Paper Cutters. It is an advanced system that uses a virtual reality interface, which is a platform that enables users to experience a computer-generated environment that simulates cutting paper in the real world. The virtual reality interface guides them through the setup and cutting process. Since the software lets them visualize the cuts they will make, it reduces the likelihood of errors. VRCut Ready Technology automates the cutting process by interfacing with digital files. This means that users can interact with digital files (like PDF files)...