News RSS

Manual vs. Automatic Paper Cutters: Which Is Better?

What Features Should You Look for in a Paper Guillotine Cutter?

Are you in the market for a paper cutter for your office? A guillotine paper cutter's versatility makes it a valuable tool in your office. That is because these machines can cut large stacks of paper. They can also help you and your employees design signs and other marketing materials. But because these machines have a large, sharp blade, operating them safely should be the focus in your office. To receive the most benefit from a paper cutter, you must know about the safety features that matter most. Read on to learn what features you should look for in a...

Trimmer or Guillotine Paper Cutter: Which Do You Need?

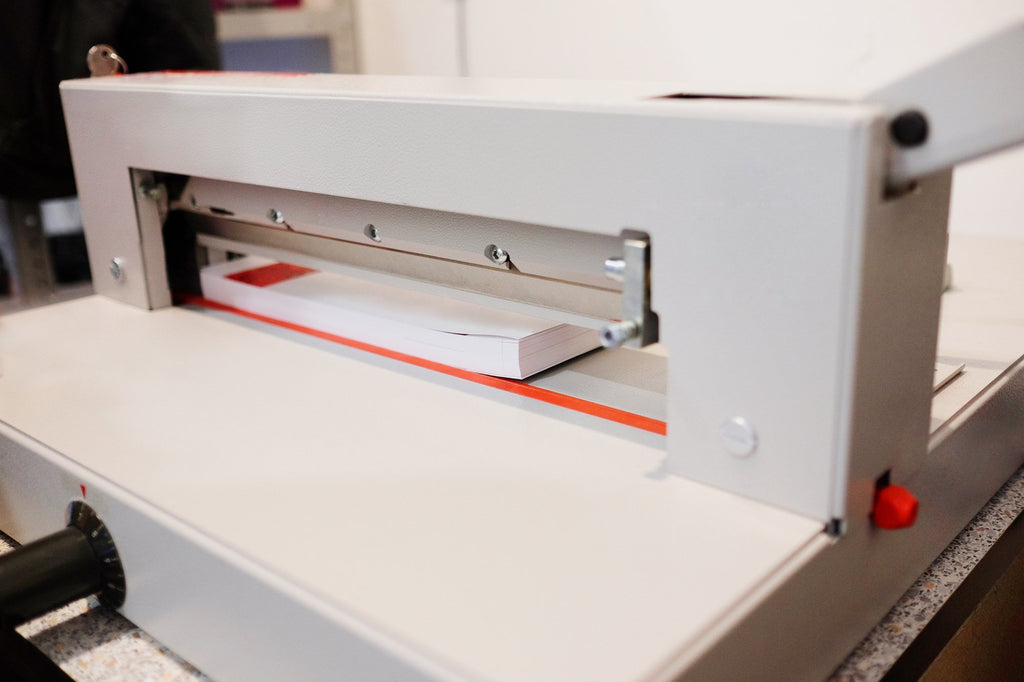

If you have a need to trim or cut paper on a regular basis, you would be well-served by investing in a paper cutting device. In general, there are two types of these devices which you can invest in: a paper trimmer and a guillotine paper cutter. While both of these paper cutting devices serve their purposes admirably, they do have differences. Trying to decide which is right for your purposes? Let's compare! Paper Trimmer Also known as a rotary paper trimmer, a paper trimmer is a device which cuts paper in a smooth, gliding style. Designed to handle a...

5 Vital Pieces of Equipment When Starting a Printing Business

Ever hear the phrase, "tools of the trade?" Every job has a specific set of tools that are required to ensure success. Bakers need a mixer and an oven. Mechanics need lifts and wrenches. Writers need a pen and paper. Sure, these examples have been oversimplified, but you can see the concept that connects them all -- it's an idea that also applies to printers. If you're considering starting a printing company, you're going to need a few tools of your own to ensure your business's success. Not sure what pieces of equipment you'll need? Don't worry we're here to...